State-of-the-Art Manufacturing Facility

Our solar module manufacturing facility is engineered to meet global quality benchmarks and high-volume production demands. Equipped with advanced automated machinery, precision-driven assembly lines, and strictly controlled environments, the facility ensures consistent output and minimal variation across every module. Backed by skilled engineers and trained technicians, each stage of production is closely monitored to deliver reliable, durable, and high-performance solar modules that meet industry standards and customer expectations.

Manufacturing Process

A streamlined manufacturing process focused on quality, accuracy, and dependable solar performance.

Wafer Production

High-purity silicon is refined and processed into uniformly sized wafers with controlled thickness and strength. These wafers form the base for efficient energy conversion and long-term reliability.

1

Cell Processing

The wafers are transformed into solar cells through advanced processing steps that enhance light absorption and electrical conductivity, enabling higher efficiency and stable performance.

2

Cell Inspecting & Sorting

High-purity silicon is refined and processed into uniformly sized wafers with controlled thickness and strength. These wafers form the base for efficient energy conversion and long-term reliability.

3

Module Assembly & Lamination

Sorted cells are interconnected and layered with glass, encapsulation, and backsheet materials. The modules are then laminated under controlled conditions to protect against moisture, heat, and mechanical stress.

4

Framing & Junction Box Installation

Anodized aluminum frames are attached for structural strength and ease of installation. Junction boxes with bypass diodes are installed to ensure safe and reliable electrical connections.

5

Testing, Inspection & Packaging

Finished modules undergo comprehensive electrical, mechanical, and visual testing. Approved modules are labeled for traceability and securely packaged for safe transportation.

6

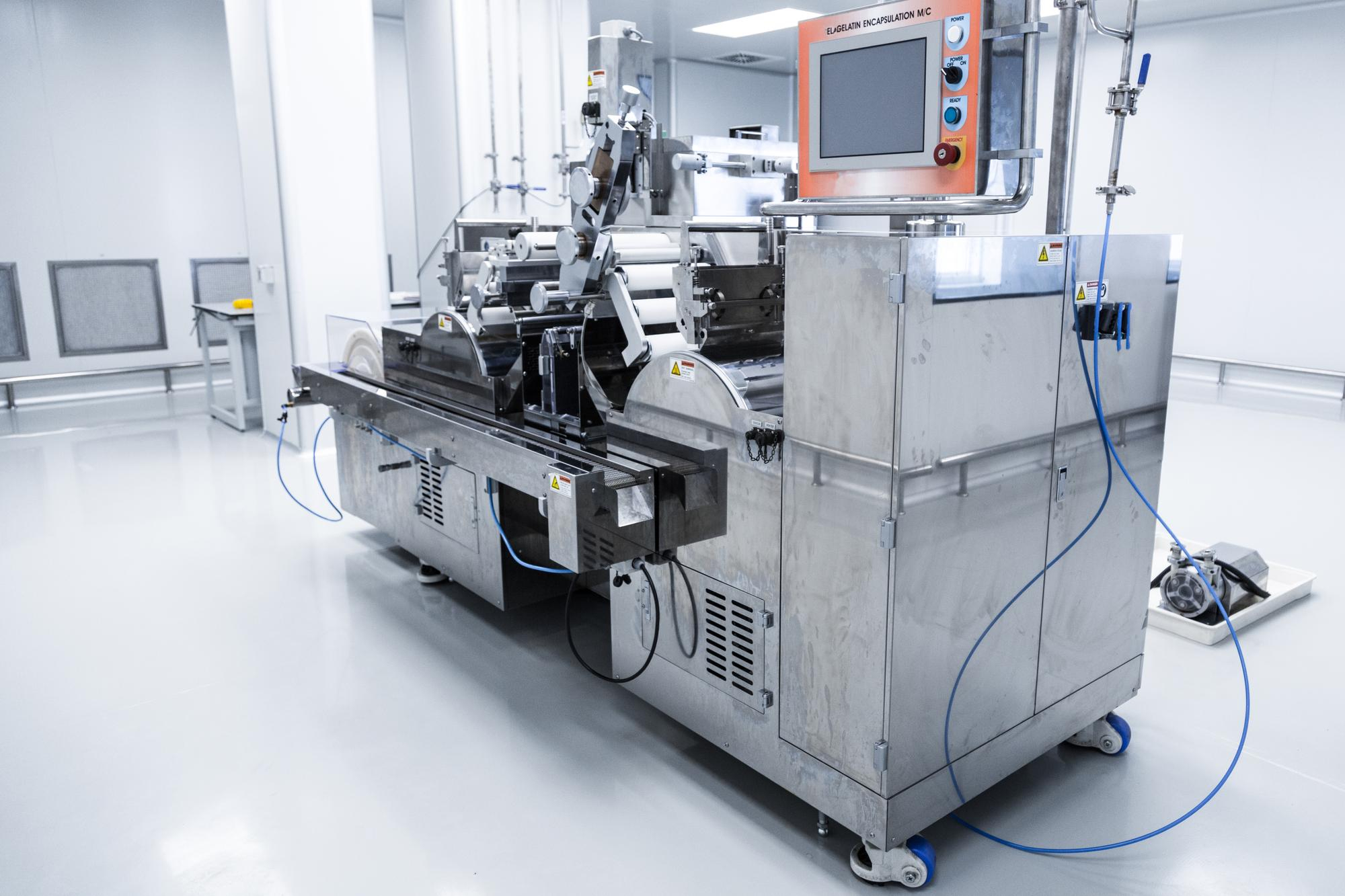

Technology & equipment

Advanced machinery and automation ensure precision, consistency, and reliable module performance.